Research on size effect

Micro/nano devices are widely applied in fields such as inkjet 3D printing, drug delivery, energy harvesting, pressure sensing, and medical devices. Understanding the mechanical behavior of materials at reduced scales is crucial for the design and fabrication of these devices. Classical continuum mechanics is commonly used to predict, analyze, and design the mechanical behavior of structures. However, as the size of the structure decreases to the micro/nano scale, a phenomenon known as the "size effect" occurs, where the stiffness increases significantly beyond what is predicted by classical continuum mechanics. Consequently, the mechanical behavior at these scales cannot be accurately predicted using classical theories alone..

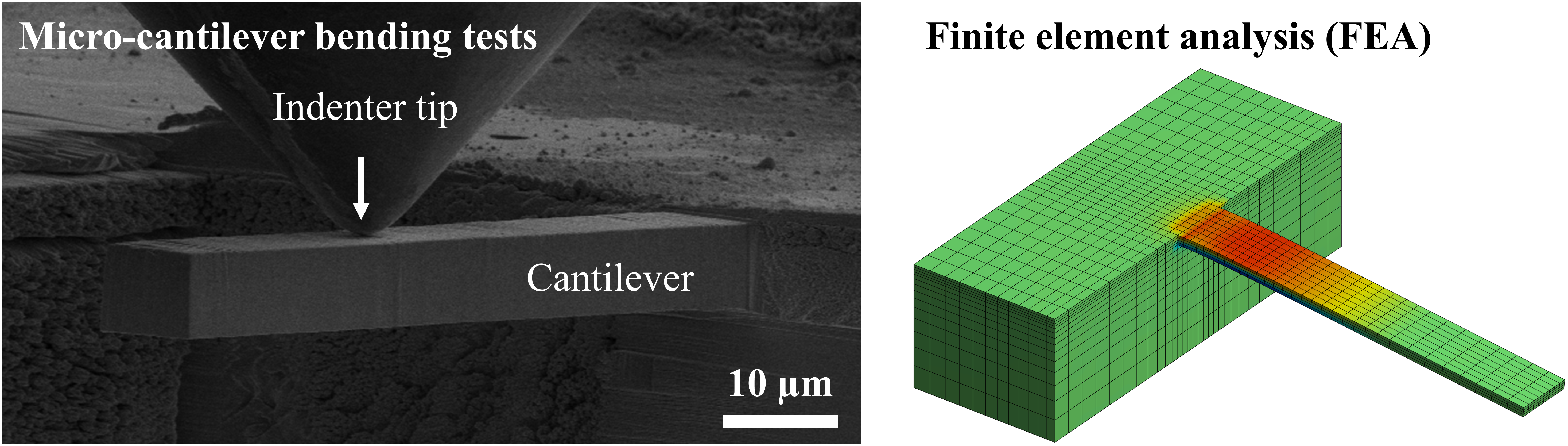

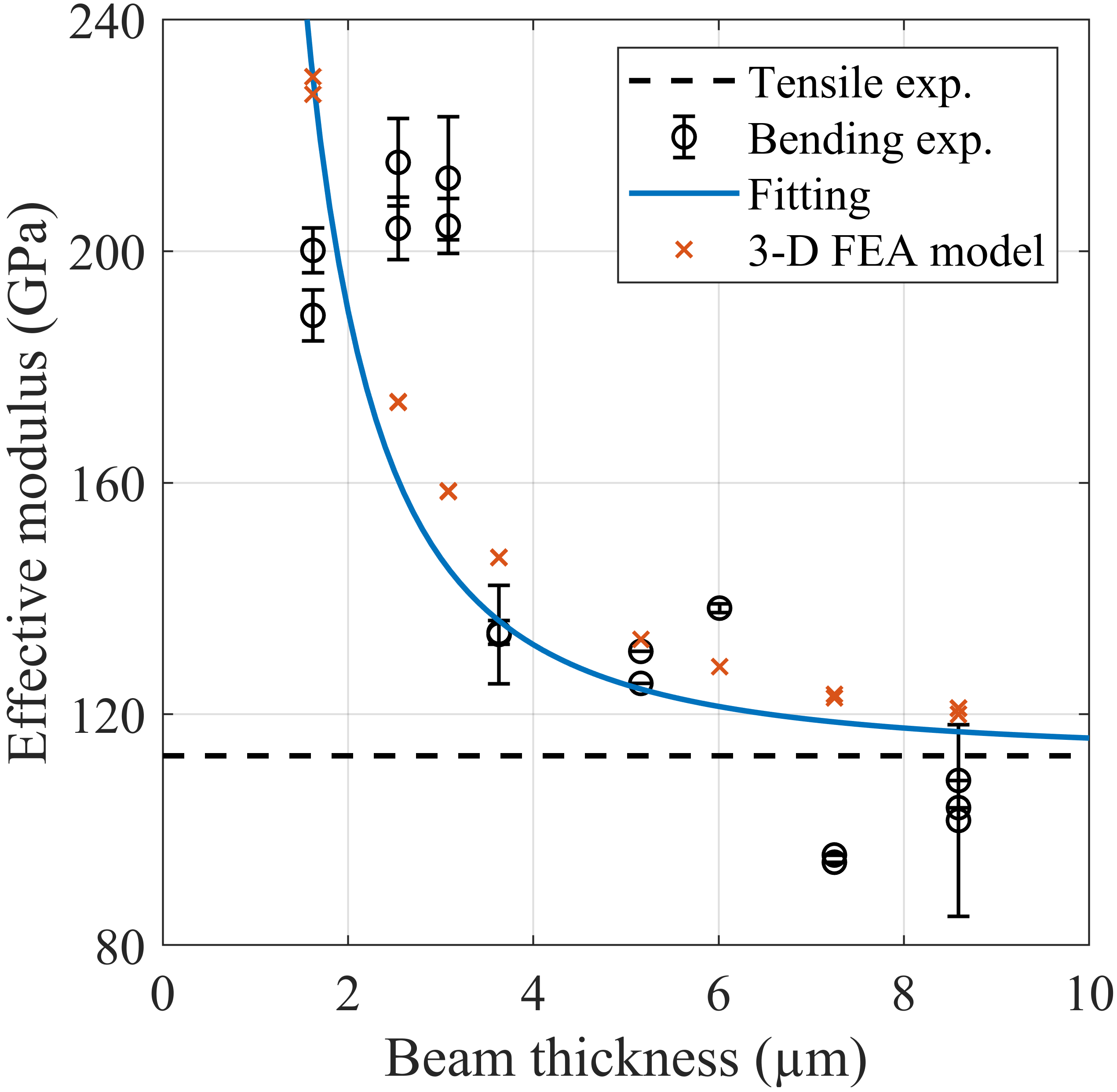

In this study, we conducted micro-cantilever bending experiments and developed a simulation method to model the size effect. According to classical solid mechanics, the elastic modulus measured from cantilever bending experiments should remain constant regardless of beam thickness. However, our experiments revealed that the effective elastic modulus significantly increases as the beam thickness decreases. This increasing trend in the effective modulus can be accurately modeled using the developed 3D finite element analysis (FEA) method. We are currently expanding this research to develop and validate analytical techniques for micro-scale structures.